PROFILE

History

Founded on 1st November 2010, Bark Innovations B.V. was incorporated to handle the development of innovative plastic packaging solutions; this came about as a result of our sister company, Bark Verpakkingen B.V., identifying a growing demand in the market for ‘personalised’ brand identity solutions.

Companies are increasingly concerned with ‘branding’, which is directed at building and enhancing their identity, we believe innovative packaging is a powerful tool in achieving this aim.

Gone are the days when everything a company needed to ’stand out’ and ‘be noticed’ on the cluttered shelves of a supermarket and DIY store was a new label or colour.

Branding is not just for the retail sector the Business to Business market is also increasingly aware of the benefits of ‘custom made’ packaging. In addition to brand identity, the desire for packaging innovation in this segment is driven primarily by rational arguments, including for example, industry’s desire to optimise their internal and external logistics processes.

Since 2006, Bark Verpakkingen B.V. has responded positively and successfully to the increasing trend for ‘custom made’ packaging but identified that clients growing expectations required enhanced specialisation.

The result is Bark Innovations B.V.

Specialisations

Look around; there is an abundance of design bureaus that will create the most stunning designs tailored to your wishes, whether in wood, plastic/foil, cans, glass, steel or gold plated titanium, virtually anything is possible on the computer or the drawing board. At Bark Innovations, we know our strengths, we also know our limitations and we attach considerable importance adopting an integrated approach that will transfer from an idea to the production line.

As well as being trained at a Technical University or Technical College, our design engineers specialise in particular areas of the production process, ensuring everything that is delivered to you as a drawing, can be produced.

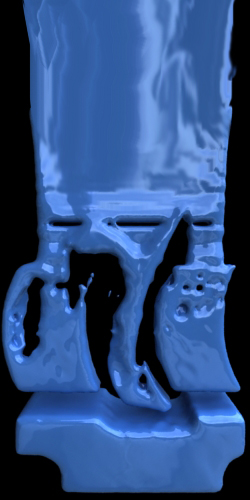

We have therefore chosen to restrict our expertise to designing innovative plastic packaging solutions that can be manufactured using one of the following techniques:

- injection-moulding

- blow-moulding

- injection-stretch blow moulding (a combination of the aforementioned techniques)

- thermoforming

We strictly adhere to the procedure: Design+Plastic+Technology=Result.

Just a simple pack?

Do you still think I am a simple pack?

I am developed to fulfil my job throughout the chain.

Philosophy

At Bark Innovations, we prefer a pragmatic, ‘down to earth’ approach. You know your market and the continuously changing needs. We know plastics and the production techniques involved in making plastics. The skill lies in integrating our respective disciplines into a design or concept that can actually be produced.

First and foremost, the concept needs to satisfy your requirements in terms of design, functionality, ease of use, environmental sustainability and of course, internal and external processes such as filling equipment and logistics. In short, this ‘set of requirements’ is a logical and indispensable part of the process to produce the desired outcome.

The integration of all the aforementioned criteria into one design or concept is achieved by drawing on specific production techniques. That way, you can be assured that all the support documentation provided by Bark Innovations, including sketches, 3D animations and prototypes are transferable into the finished article.

From idea to packaging

Combining different disciplines under one roof, Bark Innovations, in partnership with Bark Verpakkingen B.V., can establish the complete design process from the idea stage to the actual packaging. Because we manage all phases of the project, we are your one point of contact for your design, modelling, mould making, production, approvals and logistical needs.

Needless to say, you are entirely free to outsource part of the aforementioned process, for instance production, to a preferred partner.

From packaging to filling process

If you need additional support from the packaging production phase to the effective and efficient processing capability of your filling equipment, we can also be of service. Needless to say, this criterion is already taken into account during the design phase, but often a ‘fresh look’ can lead to astonishing results.

Within our network, we can call upon the expertise of design engineers who specialise in the implementation and optimisation of production processes, the development of innovative packaging provides an excellent opportunity for them to cast a knowledgeable eye over your production process, preferably in the design phase of the packaging. Here at Bark Innovations we strongly believe that our process optimisation procedures can be shown to regularly achieve measurable efficiency gains.

ractical approaches. Not through the available machinery.

Quality - ISO 9001:2015

TÜV Rheinland, the certification authority, has established that the quality system and the application thereof meet all the requirements for the field of application: Designing, developing, supply and management of (industrial) packaging.

As a result Bark’s full service package has acquired a recognition of quality from an independent accredited party.

Click here for the ISO 9001 quality certification